Offering new solutions that integrate IT with a wealth of knowledge on materials

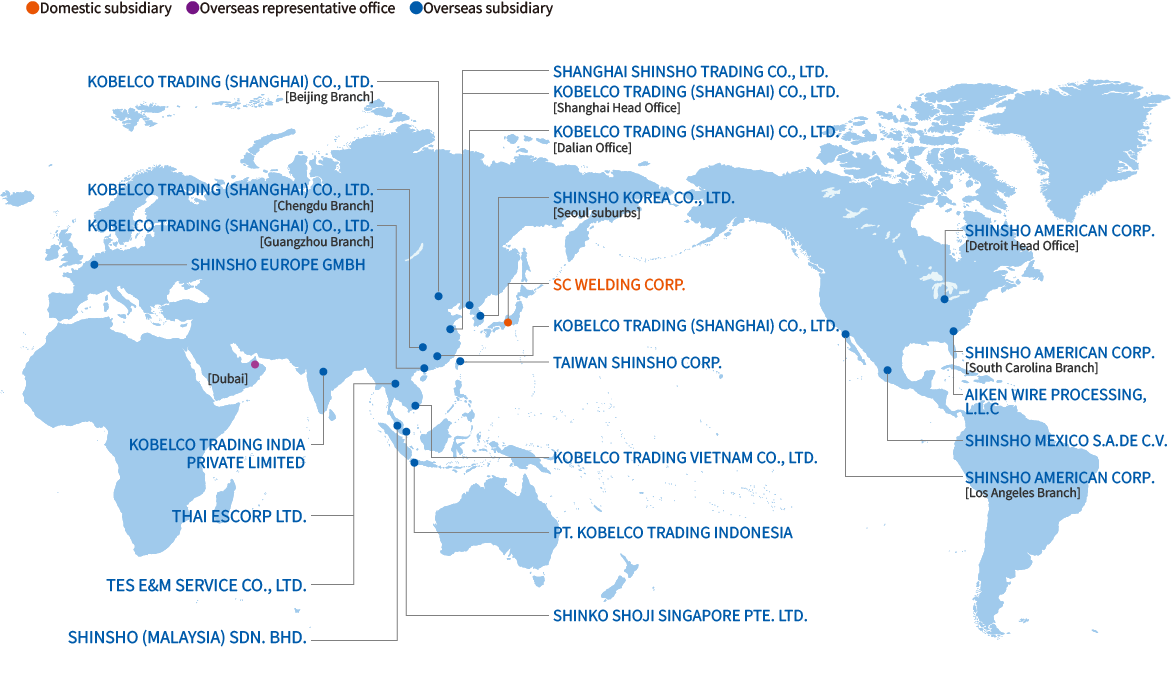

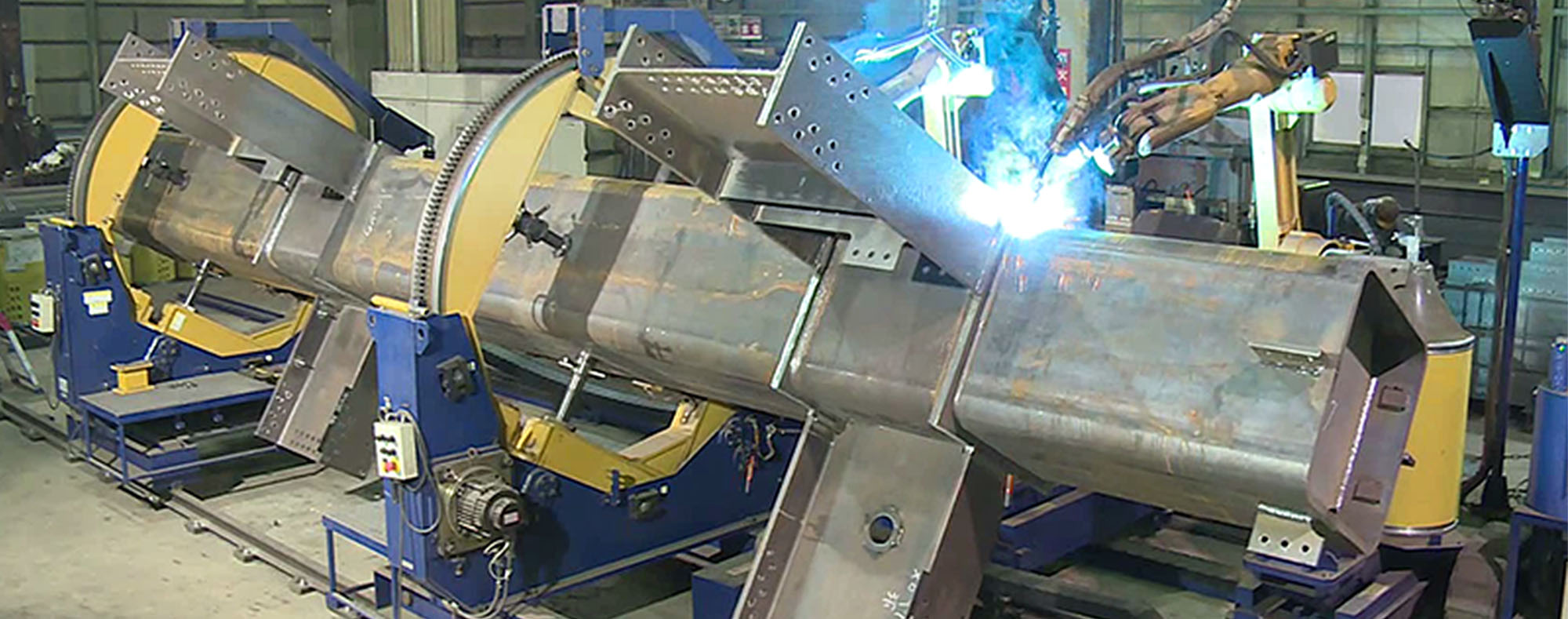

Shinsho Corporation can offer a total solutions package starting with Japan's leading welding materials from Kobe Steel all the way up to solvent materials, welding equipment, and welding robots. In 2020, the organization was restructured - including Group businesses under the Welding Unit - to strengthen our sales capabilities. We can now offer our customers new technologies and added value.

Inquiry

Inquiry